纽顿流体科技有限公司

创建时间:2006

产品类别:阀门泵阀

职务:国际贸易部经理

网址:www.bellowvalves.com,www.steamvalves.com

出口国家:More than 30 countries and regions in Europe, America, Asia, Africa and the Middle East

展品名称:波纹管截止阀,截止阀,疏水阀,波纹管闸阀,过滤器,止回阀等

最小起订量:1

订货交付时间:15

认证:CE、ISO、TS、API、TUV

买家类型:制造商、库存商/分销商、EPC、业主单位、外贸公司

VMV纽顿是一家近30年的专业阀门制造商,集阀门铸造、整机研发、生产、销售于一体。

我们已通过ISO9001体系,并通过了TS特种设备A级认证、CE、API、TUV等认证。

产品包括波纹管截止阀、疏水阀、截止阀、波纹管闸阀、止回阀、过滤器、减压阀、安全泄压阀、控制阀等,已应用于蒸汽系统、导热油系统、冷热水系统、石油工业等。

VMV纽顿还拥有自己强大的铸造厂,为全系列产品的生产提供上游供应链保障。并在永嘉五牛建立新的企业总部基地,占地50亩,总建筑面积85000平方米。

我们加大了智能设备的引进,信息化应用和数字化管理成为未来工厂建设的目标。拥有阀门CAD设计中心、三维仿真制造试验设计系统和新产品开发中心。拥有加工中心、智能专用数控机床、焊接机器人等专用加工设备,以及与欧洲领先的智能检测设备公司合作开发的自动检测设备。

产品远销欧、美、亚、非、中东等30多个国家和地区,欢迎咨询!

Bellows Seal Globe Valve

Bellows Seal Globe Valve

Application

Hot oil system, steam system, hot and cold water system etc.

Advantage

1.Bellow seal element. The key part of bellow sealed globe valves is metal bellow. It is the connection between cover and stem with automatic roll welding. The metal bellow can keep the stem part no leakage.

2.Benefit from the con and streamline shape design, the disc has a reliable seal and longer service life.

3.Double seal design(bellows+packing). Bellow and packing can protect against leakage and provide a excellent seal.

4.Grease nipple. It can direct lubricate the stem, nut and sleeve.

5.Ergonomic hand wheel. It provide longer service life and easier operation.

Technical specification

Design standard: DIN 3356

Face to face dimension: DIN 3202

Flanged ends: DIN 2543-2545

Test & inspection: DIN 3230

Nominal Pressure | PN | ||

Test Pressure | Strength test | 1.5PN | MPa |

Sealing test | 1.1PN | ||

Gas seal test | 0.6 | ||

-- | -- | ||

Suitable temp | -196℃~600℃ | ||

Bellows Seal Globe Valve

Bellows Seal Gate Valve

Bellows Seal Gate Valve

Application

Hot oil system, steam system, hot and cold water system etc.

Advantage

1.Bellow seal element. The key part of bellow sealed globe valves is mental bellow. It is the connection between cover and stem with automatic roll welding. The mental bellow can keep the stem part no leakage.

2.Double seal design(bellows+packing). Bellow and packing can protect against leakage and provide a excellent seal.

3.Grease nipple. It can direct lubricate the stem, nut and sleeve.

4.Ergonomic hand wheel. It provide longer service life and easier operation.

Technical specification

Design standard: ASME B16.34

Face to face dimension: ASME B16.10

Flanged ends: ASME B16.5

Test & inspection: API 598

Performance specification

Nominal Pressure | PN | ||

Test Pressure | Strength test | 1.5PN | MPa |

Sealing test | 1.1PN | ||

Gas seal test | 0.6 | ||

Bellows test | 1.1PN | ||

Suitable temp | -196℃~600℃ | ||

Bellows Seal Gate Valve

Globe Valve

Globe Valve

Application

Petroleum, chemical industry,pharmacy,fertilizer,power industry,etc.

Advantage

1. Disc is coniform and streamline shape design, reliable seal, longer use life.

2. Human engineering hand wheel-an enhanced design provides longer life, easy and convenient operation, more safety.

3. Steam Heat-treatment and surface nitriding-treatment to sure fuction-resistanced and friction-resistanced

Technical specification

Design standard: DIN 3356

Face to face dimension: DIN 3202

Flanged ends: DIN 2543-2546

Test & inspection: DIN 3230

Performance specification

Nominal Pressure | PN | ||

Test Pressure | Strength test | 1.5PN | MPa |

Sealing test | 1.1PN | ||

Gas seal test | 0.6 | ||

/ | / | ||

Suitable temp | -196℃~600℃ | ||

Globe Valve

Gate Valve

Gate Valve

Technical specification

Design standard: DIN 3356

Face to face dimension: DIN 3202

Flanged ends: DIN 2543-2545

Test & inspection: DIN 3230

Performance specification

Nominal Pressure | PN | ||

Test Pressure | Strength test | 1.5PN | MPa |

Sealing test | 1.1PN | ||

Gas seal test | 0.6 | ||

-- | -- | ||

Suitable temp | -196℃~600℃ | ||

Gate Valve

Check Valve

Check Valve

Advantage

1.DIN lift check valve is self-sealing valve. The disc can be acted by the flow which can protect against the media flow back.

2.The disc with spring can keep the valve work in any direction.

3.Reasonable structure, reliable sealing, excellent performance and attractive appearance make a VMV valve

Technical specification

Design standard: DIN 3356

Face to face dimension: DIN 3202

Flanged ends: DIN 2543-2545

Test & inspection: DIN 3230

Performance specification

Nominal Pressure | PN | ||

Test Pressure | Strength test | 1.5PN | MPa |

Sealing test | 1.1PN | ||

Gas seal test | 0.6 | ||

-- | -- | ||

Suitable temp | -196℃~600℃ | ||

Check Valve

Y Type Strainer

Y Type Strainer

1.DIN Y type strainer is used to separate the impurity of media. It can protect other equipment for a regular service.

2.Stainless steel filter traps make a better performance and corrosion-resistance.

3.Maintenance is easy. All you need is just clean the filter traps.

Technical specification

Design standard: DIN 3356

Face to face dimension: DIN 3202

Flanged ends: DIN 2543-2545

Test & inspection: DIN 3230

Performance specification

Nominal Pressure | PN | ||

Test Pressure | Strength test | 1.5PN | MPa |

Sealing test | 1.1PN | ||

Gas seal test | 0.6 | ||

-- | -- | ||

Suitable temp | -196℃~600℃ | ||

Y Type Strainer

Pilot Operated Pressure Reducing Valve

Pilot Operated Pressure Reducing Valve

This reducing valve is latest type pilot pressure reducing valve with membrane. It is the modified form of normal pressure reducing valve. The membrane of new material enlarging the working area, so the higher pressure can be fed back to the membrane, and adjust the main valve to maintain the constant pressure of lower pressure stream.

Advantage

1. Especially suitable for steam and water.

2. Max inlet pressure: 16 bar, 25 bar.

3. Outlet pressure (Springs pressure setting rang) Yellow: 0.2 to 3 bar; Blue: 2.5 to 7 bar; Red: 6 to 12 bar.

4. Diameter: 15-200 mm.

5. Medium temperature: 0-285 ℃.

6. Max rate inlet pressure/ outlet pressure: 20:1.

7. DIN, ANSI, GB.

Pilot Operated Pressure Reducing Valve

Safety Relief Valve

Safety Relief Valve

TECHNICAL SPECIFICATION

Design standard: DIN 3320-1999

Face to face dimension: DIN 3202-1999

Flange standard: DIN 2543-2545

Test & inspection: DIN 3230

Safety Relief Valve

Thermodynamic (disc) Steam Trap

Thermodynamic (disc) Steam Trap

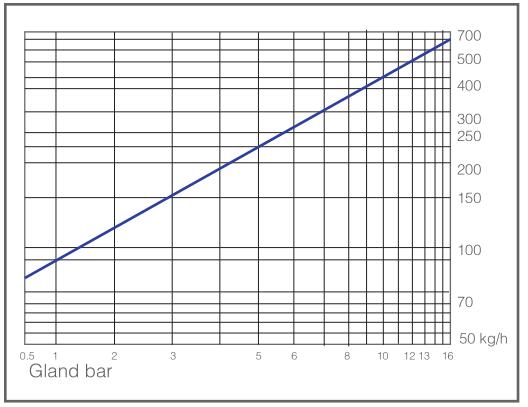

STD16 Displacement Curve

Applications

1. The steam transmission pipeline guide.

2. Small heat exchanger and kettle.

3. Heating system.

4. The small coil is heated by air.

Material

Cap | A105 |

Valve Body | A105 |

Seat | Stainless Steel |

Disc | Stainless Steel |

Other Internals | Stainless Steel |

Data Size Table

Type | Conn | DN | PN | Working Pressure MPa | Temperature°C Pressure MPa | Diameter (mm) | U.W Kg | |||

L | H | H1 | W | |||||||

STD 16T | Thread | 15-25 | 25 | 0.05-1.6 | 400/1.57 | 90 | 120 | 120 | 48 | 1/1.5 |

STD 16W | SW | 15-25 | 25 | 0.05-1.6 | 400/1.57 | 90 | 120 | 120 | 48 | 1/1.5 |

STD 16F | RF | 15-25 | 25 | 0.05-1.6 | 400/1.57 | 150 | 120 | 120 | 48 | 2.5-3 |

Thermodynamic (disc) Steam Trap

Thermostatic (bimetal) Steam Trap

Thermostatic (bimetal) Steam Trap

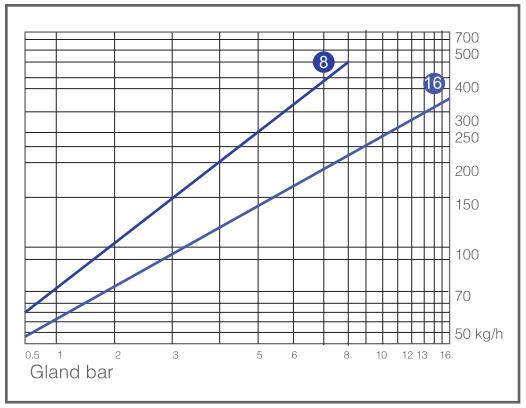

SHT16/32 Displacement Curve

Applications

1. The steam transmission pipeline guide.

2. Small heat exchanger and kettle.

3. Heating system.

4. The small coil is heated by air.

Material

Cap | A105 |

Valve Body | A105 |

Seat | Stainless Steel |

Disc | Stainless Steel |

Other Internals | Stainless Steel |

Data Size Table

Type | Conn | DN | PN | Working Pressure MPa | Temperature°C Pressure MPa | Diameter (mm) | U.W Kg | |||

L | H | H1 | W | |||||||

SHT 16/32T | Thread | 15-25 | 63 | 0.05-3.2 | 400/1.57 | 90 | 145 | 68 | 55 | 1.8 |

SHT 16/32W | SW | 15-25 | 63 | 0.05-3.2 | 400/1.57 | 90 | 145 | 68 | 55 | 1.8 |

SHT 16/32F | RF | 15-25 | 63 | 0.05-3.2 | 400/1.57 | 150 | 145 | 68 | 55 | 4 |

Thermostatic (bimetal) Steam Trap

Inverted Bucket Steam Trap

Inverted Bucket Steam Trap

DT inverted trap has special lever structures, extensively applied industries of petroleum, textile, foods, paper making, chemical industry and steam pipelines.

Advantages

1. Simple structure, no gemel structure, no fixed abrasive, excellent abilities to save energy, valve base is made of chrome steel, with long service life.

2. The waste discharged constantly will be washed away, no dirty remained, and the air will be automatically discharged.

3. The parts are all fixed on the valve cover to facilitate maintenance.

Inverted Bucket Steam Trap

Lever Float Steam Trap

Lever Float Steam Trap

SFT10 Displacement Curve

Applications

1. The steam transmission pipeline guide.

2. Small heat exchanger and kettle.

3. Heat tracing system (high back pressure recovery system)

4. The coil is heated by air.

Material

Cap | A105 |

Valve Body | WCB |

Seat | Stainless Steel |

Disc | Stainless Steel |

Other Internals | Stainless Steel |

Data Size Table

Type | Conn | DN | PN | Working Pressure MPa | Temperature°C Pressure MPa | Diameter (mm) | U.W Kg | |||

L | H | H1 | W | |||||||

SFT 10T | Thread | 15-25 | 25 | 0.05-1.6 | 400/1.57 | 150 | 120 | 60 | 170 | 5.5 |

SFT 10W | SW | 15-25 | 25 | 0.05-1.6 | 400/1.57 | 150 | 120 | 60 | 170 | 5.5 |

SFT 10F | RF | 15-25 | 25 | 0.05-1.6 | 400/1.57 | 210 | 120 | 60 | 170 | 8 |

Lever Float Steam Trap

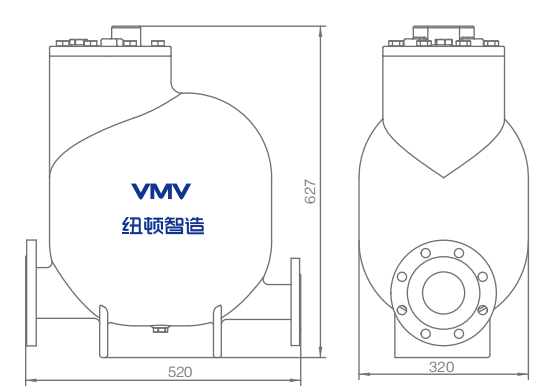

Pump Steam Trap

Pump Steam Trap

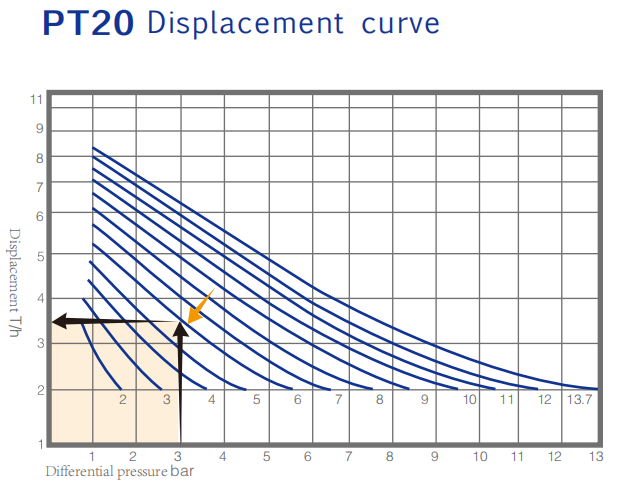

The condensate recovery pump has a series of advantages such as automatic control, no cavitation, simple maintenance, no electricity, water hammer resistance, large displacement, explosion-proof, no noise, and the pressure of the power steam determines the head. It is unmatched by other electric pumps.

It is widely used in the recovery of steam condensate and the transportation of low-viscosity non-volatile liquids.

Working Principle

The pump trap has two strokes:

1.Inlet water and exhaust steam: At the beginning, the inlet check valve is opened, and the outlet check valve is closed due to high back pressure. At the beginning, the water inlet and exhaust valves in the valve are opened, and the float is in a low position. As the water level rises, the float When reaching the highest, the controller is in the state of switching zero boundary.

2.Inlet steam and drainage: the controller starts to switch at a high position and closes the exhaust valve; opens the power steam, injects steam into the valve, and pushes the condensate in the pump to the high pressure area under the push of steam pressure, then the inlet check valve Due to the high pressure inside the valve, water cannot enter. When the float reaches a low position, the controller switches to close the power steam, opens the exhaust valve, and enters the next action cycle.

Note

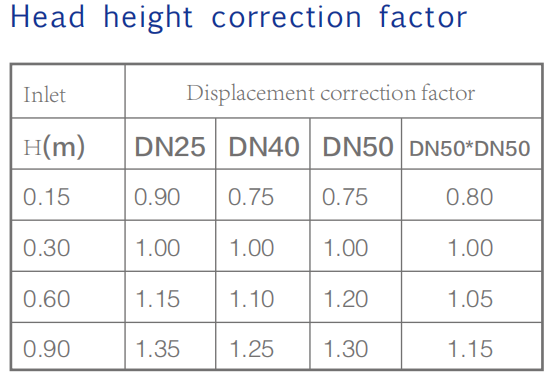

● It is recommended that the head height of the fluid entering is0.5m or more (the pump cover is the reference), you can refer toTake the "Correction Factor for Water Ingress Height";

● The power steam inlet is connected to RC1/2”;

● For the normal operation of the pump, the saturatedcondensate needs to be flashed or condensed.The type system must ensure the pressure difference and backpressure rate for the normal operation of the trap.

● The standard configuration of condensate inlet and outlet isHG/T20592-2009 PN16 flangeFor connection, if you need other standards such asASME16.5, JIS, etc., please specify.

Step 3: Shift the intersection point to the left to find the displacement value, and get the displacement of 3.5t/h.

Step 4: 3.5t/h x head height correction factor = actual displacement;

Pump Steam Trap

Condensate Recovery System

Condensate Recovery System

Restrictions: The collecting tank (upper tank) is unpressurized and is only used as an open buffer tank.

Condensate Recovery System

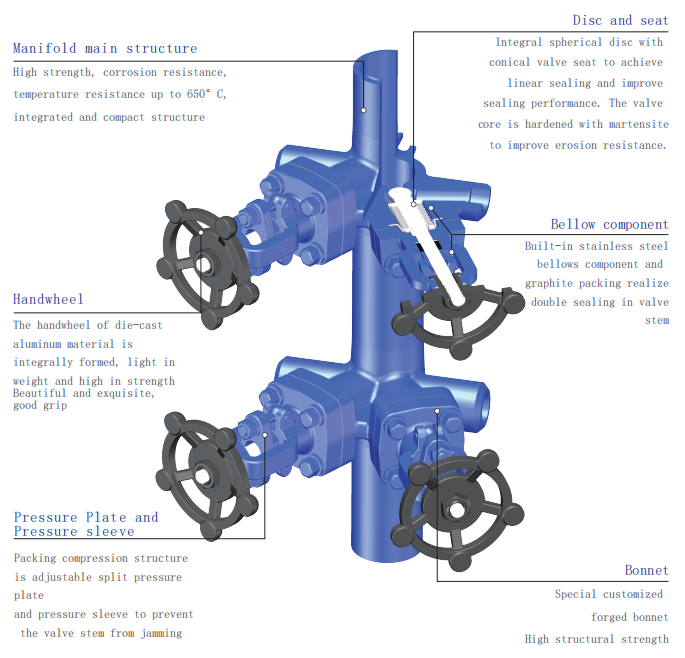

Forged Steel Bellows Condensate Manifolds

Forged Steel Bellows Condensate Manifolds

VMV Newton’s " forged steel Bellows condensate manifolds" has a built-in one-piece forged A105 bellows globe valve. The BSPM02 and BCRM02 series products are used for steam distribution or condensate collection respectively, and are suitable for instrumentation, pipeline heating, and process heating. According to the user's design and requirements, multiple bellows stop valves, drain valves, and drain traps are integrated on each manifold. It can also be equipped with base bracket, heat preservation prefabricated heat tracing pipe, union clamp, matching flange and other components. Has the same characteristics as the Bellow stainless steel condensate manifolds.

Forged Steel Bellows Condensate Manifolds

Vacuum Breaker

Vacuum Breaker

SKT16 Displacement Curve

Applications

1. The steam transmission pipeline guide.

2. Small heat exchanger and kettle.

3. Heating system.

4. The small coil is heated by air.

Material

Cap | A105 |

Valve Body | WCB |

Seat | Stainless Steel |

Disc | Stainless Steel |

Other Internals | Stainless Steel |

Data Size Table

Type | Conn | DN | PN | Working Pressure MPa | Temperature°C Pressure MPa | Diameter (mm) | U.W Kg | |

L | H | |||||||

SKT 16T | Thread | 15-25 | 16 | 0.05-1.6 | 350/1.57 | 75 | 55 | 1 |

SKT 16F | SW | 15-25 | 16 | 0.05-1.6 | 350/1.57 | 120 | 125 | 2.8 |

Vacuum Breaker